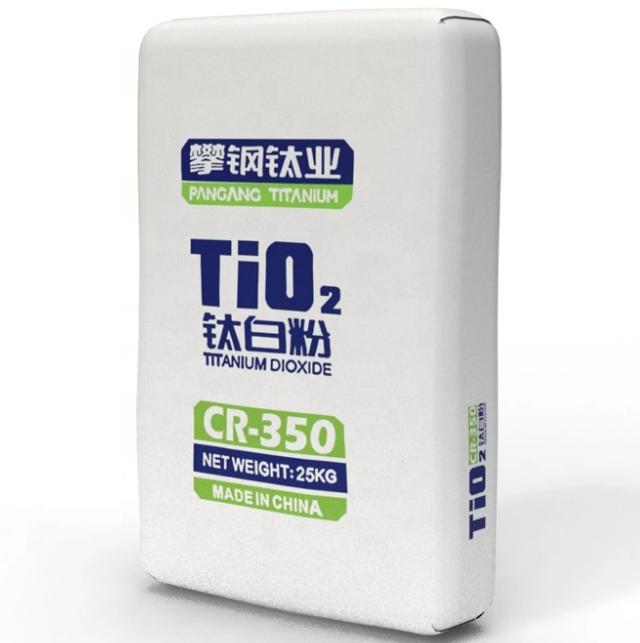

Another important factor to consider when choosing a TiO2 supplier is their commitment to sustainability and environmental responsibility

- Moreover, the compact and portable nature of butyl rubber tape makes it an indispensable tool for on-site repairs. It can be stored conveniently without fear of hardening or losing its adhesive properties, ensuring it's always ready when needed. This feature, combined with its resistance to punctures and tears, makes it a go-to solution for emergency repairs in remote or challenging locations.

What is Polyethylene Tape used for?

Quality Assurance: certifications and quality standards ensure that you're investing in a reliable and effective product.

In addition to its insulating properties, yellow tape is also useful for temporary markings. Electricians frequently work in environments where systems are being modified. In these situations, marking specific wires, circuits, or components temporarily can help maintain organization and ensure that everyone on site is aware of the current configuration. Whether it’s to indicate a wire that is to be rerouted or to label a circuit that is being serviced, the bright color of yellow tape offers high visibility, reducing the likelihood of accidental disconnections or mishaps.

Acrylic adhesives can either be water-based (this is also referred to as emulsion or dispersion) or solvent-based. Water-based are slower drying compared to solvent-based systems but generally solvent-based acrylic systems have better resistance to other solvents, chemicals and water. Comparatively, water-based systems are less expensive than their solvent-based counter parts.

It helps in visually identifying where items belong, ensuring a systematic approach to housekeeping and organization It helps in visually identifying where items belong, ensuring a systematic approach to housekeeping and organization

It helps in visually identifying where items belong, ensuring a systematic approach to housekeeping and organization It helps in visually identifying where items belong, ensuring a systematic approach to housekeeping and organization warehouse marking tape. This not only enhances the overall cleanliness of the warehouse but also contributes to a more efficient inventory management system.

warehouse marking tape. This not only enhances the overall cleanliness of the warehouse but also contributes to a more efficient inventory management system. The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with

The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with The vibrant colors and adhesive properties of the tape make it a fun and easy material to work with colored pvc tape. Crafters can use PVC tape to create decorative borders, accents, or patterns on various surfaces. The tape can also be easily cut, folded, and layered to achieve different artistic effects.

colored pvc tape. Crafters can use PVC tape to create decorative borders, accents, or patterns on various surfaces. The tape can also be easily cut, folded, and layered to achieve different artistic effects.THE BENEFITS OF 3M RUBBER ELECTRICAL TAPES

However, it is also essential to consider the limitations of Black Flex Tape. While it offers excellent short-term and mid-term solutions, it may not always be suitable for long-term structural repairs. In cases where heavy-duty strength and durability are required, additional methods or materials might still be necessary. Though it excels at providing temporary fixes, users should remain mindful of the contexts in which they are applying it.

To achieve optimal results with butyl weather stripping, follow these simple steps

Our Self-Fusing Tape Range.

The Versatile Utility of Flex Tape A Comprehensive Look at Flex Tape White 4x5

Butyl rubber strip is also known for its superior adhesion properties, allowing for easy installation and secure bonding to various substrates. Whether used on metal, plastic, or glass surfaces, butyl rubber strip provides a strong and reliable seal that resists displacement and maintains its integrity over time.

5. Chemical Resistance

Due to its unique adhesive, water-activated tape cannot be applied by hand. It needs to be applied with a specialized dispenser. Luckily, good tape dispensers are durable, reusable, and easy to find online. Plus, applying tape with a dispenser results in neater, more professional-looking packaging compared to tape that has been applied manually. The dispenser will require minimal cleaning and adjustment. In return, it will provide your business with an efficient way to safely package your products.

Polyethylene film tape (63535) is a 7-mil thick tape coated on one side with a synthetic rubber adhesive. This particular tape is UV-resistant and can form a water-tight seal, making it a good tape for outdoor use. It is designed to be able to mask windows and doors in stucco fabrication and other construction applications. This tape is available in white or red. Available widths range from 2 inches (48 millimeters) to 44 inches (1,118 millimeters).

In addition to being built differently than other tapes, most electrical tapes used by professionals are UL Listed, which means that they have been vigorously tested for performance when exposed to environmental elements, such as cold temperature, moisture, and sunlight. UL Listed electrical tapes are also tested for physical properties, including backing strength, elongation, and adhesive strength and must meet a high standard in order to qualify for the listing. UL Listings exist for many other types of tape – such as foil and film HVAC tapes – but each listing revolves around the specific type of tape in question. So, while your foil tape may meet UL Listing requirements for sealing rigid ducts in HVAC applications, it would not meet the code if used in an electrical application.